When the heat is on, you need to make sure the right protective gloves are, too. Thermal risks posed by heat or fire are common in many sectors, including automotive, construction and food handling.

The EN407 standard covers gloves that protect against thermal risks (heat and/or fire). It applies to heat-resistant gloves for professional and consumer use, but not to those worn by firefighters and welders, to which separate standards apply. It tests the thermal performance of glove material for the following:

- Limited flame spread

- Contact heat resistance

- Convective heat resistance

- Radiant heat resistance

- Resistance to small splashes of molten metal

- Resistance to large quantities of molten metal

There are four performance levels (from level 1 lowest to level 4 highest) for each test. EN407 also contains a mechanical test requirement for tear resistance, the method for which is the same as in EN388: 2016 (to find out more about this standard, see our EN388 gloves blog). Nitrex 370W Thermal Industrial Gloves by Unigloves, for example, offer level 4 tear resistance as well as contact heat protection to 100°C.

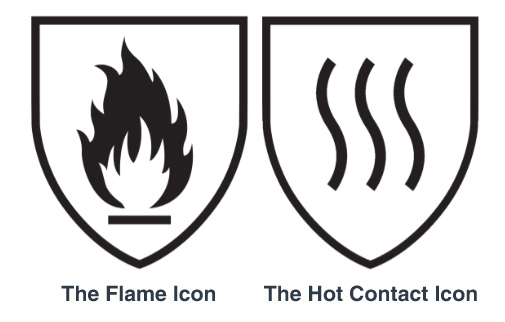

Gloves that have passed at least one of these tests of protection from thermal risks are marked with one of the two following symbols:

The ‘flame’ icon can be applied to products that have achieved at least level 1 performance in the limited flame-spread test (see below). The ‘hot contact’ icon is applied to products that do not claim to limit flame spread but did achieve at least level 1 performance in one other test.

The icon will be accompanied by six digits that indicate the levels of performance achieved by the glove in each test (in the order listed above). A zero means the product failed the test, while X means it was not subjected to that test. The use of both symbols together on a product is not allowed.

Burning behaviour: The limited flame spread test in EN407

This tests the ability of the glove to protect the wearer’s hand from a naked flame according to EN ISO 15025:2016. A glove does not need to be inflammable to pass the test, but it must burn slowly enough for the wearer to react and remove the glove safely.

In the test, the end of the middle finger of the sample glove is exposed to a small gas flame for 10 seconds. The flame is then removed and the lengths of time for which the glove material glows or burns afterwards are recorded.

Performance levels for burning behaviour tests

The innermost surface of the glove is also visually checked for any sign of melting (which would mean a test fail). No hole shall appear on all layers of the tested area. The seam shall not come apart after the ignition time.

Note that in order to claim performance levels 3 or 4 in any of the other five tests (see below), a minimum rating of level 3 must be achieved by the glove in the limited flame-spread test. If not, the maximum performance level that can be claimed for any of the other thermal properties is level 2.

Contact heat resistance

Contact heat is the transfer of heat through solid or physical matter, e.g., from a hot item to the person’s hand holding it. The amount of heat transferred depends on various factors, such as surface area, the temperature of the hot item and the pressure of the contact.

The method for testing the level of protection provided by gloves against contact heat is EN ISO 12127-1:2015. It involves testing the palm region of the gloves (as well as any other areas that are intended to be exposed to contact heat and thus protect the wearer from it). A metal cylinder is heated to a different starting temperature, depending on the level of performance being claimed.

The time taken for the temperature on the underside of the sample to rise to 10°C above the starting temperature is then measured using a device called a calorimeter. The glove must withstand the increasing temperature up to the maximum of 10°C for at least 15 seconds (the ‘threshold time’). For performance levels of 3 or 4, the limited flame spread test shall be performed. The product shall reach at least level 3 in the limited flame spread test, otherwise, the maximum contact heat performance that shall be reported is level 2.

Performance levels for contact heat tests

Nitrex 440 Chemical Resistant Gloves by Unigloves are certified to performance level 2 under EN407, meaning they are contact-heat resistant up to 250°C.

Convective heat resistance

Convection is the transfer of heat by the motion of a liquid or gas. It is tested under EN407 according to the method in EN ISO 9151:2016. This involves exposing the sample (again, from the palm and any other areas intended to be exposed to contact heat) to the heat from a controlled gas flame.

A calorimeter on the inside of the glove is used to measure the rate of temperature rise. This time, the four performance levels are determined according to the heat transfer index (HTI), i.e., the rate at which the temperature rises by a specified amount in a specified amount of time. For performance levels of 3 or 4, the limited flame spread test shall be performed. The product shall reach at least level 3 in the limited flame spread test, otherwise, the maximum convective heat performance that shall be reported is level 2.

Performance levels for convective heat tests

Radiant heat resistance

Thermal radiation is the heat exchange between physical objects in the form of electromagnetic waves. It can be very intense and cause injury without contact being made with the heat source. The test method used is method B of EN ISO 6942:2002.

A sample from the glove is exposed to a specific level of radiant heat and a calorimeter is used to record when a temperature rise of 24°C occurs. These data are then used to calculate the percentage heat transmission factor. For performance levels of 3 or 4, the limited flame spread test shall be performed. The product shall reach at least level 3 in the limited flame spread test, otherwise, the maximum radiant heat performance that shall be reported is level 2.

Performance levels for radiant heat resistance tests

Small splashes of molten metal

Molten metal is, obviously, extremely hot, so should it splash onto someone’s hands, the key is not only to prevent contact with the skin but also to minimise the time of any contact with protective gloves. To measure a glove’s resistance to small splashes of molten metal, testing is carried out in accordance with EN348:1992. Drops of molten metal weighing 0.5 g are applied to the outer glove at a specified rate.

The number of droplets it takes to raise the temperature on the underside of the glove by 40°C is measured. For performance level 1, this must take 10 drops of molten metal or more. For level 4, it must take 35 or more. Following the droplet test, the sample is inspected for signs of melting and, in the innermost layer, holes. For performance levels of 3 or 4, the limited flame spread test shall be performed. The product shall reach at least level 3 in the limited flame spread test, otherwise, the maximum small splashes of molten metal performance that shall be reported is level 2.

Performance levels for small splashes of molten metal

Large quantities of molten metal

In this test, which is conducted in accordance with EN ISO 9185:2007, specified quantities of molten metal (iron) are poured onto the sample. The PVC sensor film mounted behind the test sample (to simulate skin) is visually inspected for any signs of smoothness or other changes to the grain. A glove that ignites during the test will fail it. For performance levels of 3 or 4, the limited flame spread test shall be performed. The product shall reach at least level 3 in the limited flame spread test, otherwise, the maximum large quantities of molten metal performance that shall be reported is level 2.

Performance levels for large quantities of molten metal

Understanding the performance levels claimed for gloves that provide heat protection is crucial to ensuring the right protective gloves are selected for tasks and settings that pose thermal risks. To determine the most suitable hand protection for your workplace or task, browse the Unigloves range or contact our team for details of your nearest Distributor.

The Unigloves Nitrex range of industrial gloves has been developed to be extremely comfortable and dextrous, as well as protective against a range of specific hazards. Browse the range for EN407-compliant products that protect against thermal risks or contact our team to find your nearest Distributor.

To learn more about EN standards as they relate to protective gloves, download our Glove EN Standards Guide.