- Blue / Black nitrile double dipped, light duty gloves

- Features Unigloves NitreGrip Technology, a new advanced surface treatment that provides an assured grip when working in dry, wet or oily conditions

- Features Unigloves NitreGuard Technology which is awarded to gloves achieving a high-performance in the straight blade cut test

- Light weight seamless, breathable, nylon liner with HPPE, encapsulated glass fibre and steel provides an excellent level of cut protection

- The sandy nitrile coating is resistant to oils and grease acting as a physical barrier. In addition, the sandy nitrile gives exceptional grip in dry, wet and oily environments

Nitrex 340FCD Cut Resistant Gloves

For over 30 years, Unigloves has been your trusted partner in personal protective equipment. Producing an extensive range of safety gloves designed to fit seamlessly into your PPE regime for superior hand protection, ongoing comfort, and maximum performance, our safety gloves are some of the most widely sought-after in the market. An industry leader in Europe, the UK, and throughout the world, Unigloves’ reputation speaks for itself.

In the development of our latest range, Unigloves Nitrex, we have incorporated a number of advanced manufacturing technologies to bring you a high-quality and highly protective collection of work gloves. Robust, hard-wearing, and extremely versatile, our Nitrex gloves can take on the challenges your workplace presents.

Our NitreGrip™ Technology is an advanced surface treatment developed by Unigloves to provide an assured grip when working in dry, wet, or oily conditions. The technology reduces the force needed to grip, thus reducing hand fatigue and ensuring your safety glove never compromises performance.

Another of our advanced technologies, Unigloves NitreGuard™ Technology, is awarded to gloves achieving high-performance in the straight blade cut test for European standard EN388: 2016.

Our Nitrex 340FCD Cut Resistant Gloves comprise both NitreGrip and NitreGuard technologies to provide you with a highly protective work glove, resistant to high-level risks and ensuring outstanding grip in any conditions.

Nitrex 340FCD user benefits:

• Featuring Unigloves NitreGuard Technology

• Featuring Unigloves NitreGrip Technology

• 13 gauge seamless liner comprising HPPE, encapsulated glass fibre and steel core

• Cut resistant level F (highest level, equivalent to level 5)

• Dual nitrile coating

• Sandy nitrile palm coating

• Excellent abrasion and tear properties

• Food approved, except with acidic foods

• Elasticated knitted wrist

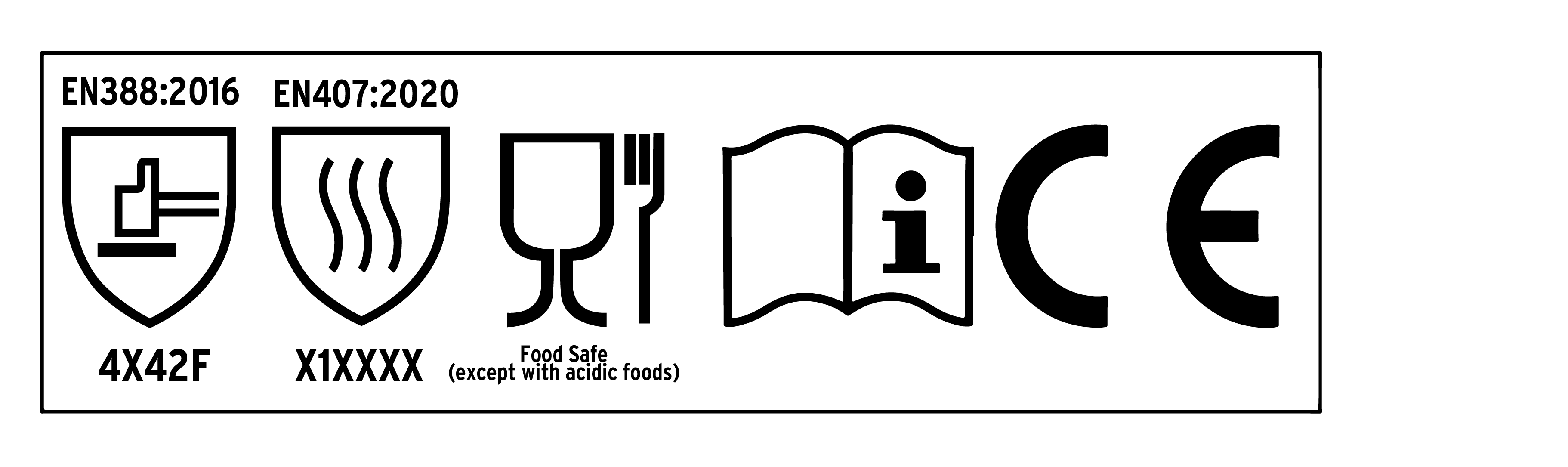

• Tested to EN388 and EN420

Unigloves NitreGuard Technology is awarded to gloves achieving a high-performance in the straight blade cut test. Our Nitrex 340FCD has achieved a cut level F rating, equivalent to cut level 5, and representing the maximum cut protection available. So, no matter the high-level cutting threats present in your workplace, you can rest assured that your workers’ hands are afforded the best protection available.

Of course, protection against cuts is not the only factor to consider when choosing a safety glove for your workplace. Your chosen glove should also ensure ongoing comfort and performance so that hands are not put at risk. Our NitreGrip Technology is a new, advanced surface treatment that provides an assured grip when working in dry, wet, or even oily conditions. This ground-breaking technology reduces the force needed to grip, thus reducing hand fatigue and ensuring an effortless hold on parts and materials in some of the more challenging conditions your workplace presents.

The light weight, seamless 13 gauge nylon liner of our Nitrex 340FCD is constructed with HPPE, encapsulated glass fibre, and steel to provide the maximum level of cut protection whilst remaining breathable, comfortable, and ensuring ongoing comfort throughout the day.

The 340FCD’s flexible dual nitrile coating comprises a fully coated, flat nitrile base layer that affords liquid resistance to the wearer and full 360° hand protection. Meanwhile, the sandy nitrile palm coating is resistant to both oils and grease and acts as a physical barrier against these and other liquids. In addition, the comfortable and flexible sandy nitrile coating helps to deliver dexterity to the wearer, which assists in performing more precise tasks. To further enhance comfort and protection, the elasticated wrist ensures a secure fit and keeps hands free from dust ingress.

Sectors and applications

There is no better choice for maximum cut protection in your high-risk applications than Nitrex 340FCD, which features both Unigloves NitreGuard and NitreGrip Technologies. The ideal safety glove solution for high-level cut risks and providing excellent dry, wet, and oily grip, Nitrex 340FCD nitrile dipped gloves keep hands safe in some of the most challenging environments. Offering protection against liquid ingress, as well as excellent abrasion and tear resistance, you can rest assured that hands are protected all day long without compromising on performance or comfort.

Unigloves Nitrex 340FCD cut level 5 gloves (equivalent to cut level F for European standard EN388:2016) are ideally suited to the following sectors:

• Construction

• Engineering

• Glass handling

• Local authority

• Recycling

• Manufacturing

• Railway maintenance

• Transportation

• Utilities

• Brewery

• Food

• Fisheries

Some of the applications these nitrile dipped gloves are suited to include:

Construction: Conditions in the construction industry can be unpredictable, which means you need a high performance glove with high cut protection and exceptional grip, even in the wet or when handling oily parts. Nitrex 340FCD is an ideal choice of glove for the range of different construction activities undertaken from demolition to bricklaying to pipe laying to operating heavy equipment.

Bottling: For industrial bottling applications, a cut resistant glove is non-negotiable. Regular contact with glass bottles and potentially dangerous bottling machinery means the risk of cuts, tears, and abrasions. Furthermore, bottling applications can involve the added complication of wet or greasy material handling, which can result in compromised grip if using an inappropriate glove. Nitrex 340FCD provides an assured grip in dry, wet, and even oily conditions, as well as maximum cut protection (level F) against glass, metals, and other sharp or abrasive objects.

Waste handling: Handling of waste can present several risks to workers, including cuts from sharp objects and tear and abrasion hazards from a variety of materials. For an outstanding grip in all conditions – including wet and oily environments – and the maximum cut protection rating afforded to any safety glove, look no further than Nitrex 340FCD.

Treated with both Unigloves NitreGuard Technology and NitreGrip Technology, Unigloves Nitrex 340FCD is one of the most highly protective gloves in our range. Resistant to oils and grease and providing second-to-none grip, these gloves provide maximum cut protection and excellent tear and abrasion resistance. Featuring a flexible dual nitrile coating consisting of a fully coated, flat nitrile base layer providing liquid resistance to the wearer and full 360° hand protection, Nitrex 340FCD keeps hands protected against all manner of hazards present in your workplace. For superior hand protection, comfort, and performance, select Nitrex 340FCD as your preferred safety glove.